For all companies aiming for quality development and growth, embracing changes is imperative. Options for transformation through the implementation of IT systems, which automate various processes, are available at every turn. The question, however, lies in whether the implementation of an IT product will genuinely address all the organization's issues. What if it introduces new ones?

Three crucial components are essential for the development of any business: changes, changes, and... changes once again. Business gurus, top managers of multinational companies, domestic and foreign consultants emphasize the necessity of constant transformations. Everyone insists on transformation, and it is indeed crucial. However, few focus on the significant "but": changes for the sake of change are worthless. Yet, the leadership of many companies stumbles precisely on this point. Therefore, let's explore the principles of proper transformation using the example of automated systems, the application of which is often referred to as a competitive advantage, without specifying exactly what it entails.

|

Our TOP software for 2024 ✔️ Thryv ✔️ Salesforce ✔️ monday.com ✔️ Pipedrive |

3 Key Strategies for Implementing an ERP System

Step-by-Step Integration:

In this approach, ERP automation is carried out on several core modules. After their configuration, the gradual implementation of the ERP system takes place across all business areas. The drawback is that this method takes a considerable amount of time, and the impact of system implementation may not be immediately noticeable.

Comprehensive ERP Implementation

This strategy involves implementing the program all at once and in full scope across all business functions. We recommend this option for companies with a straightforward organizational structure and production processes. This approach requires thorough testing of all processes, as it is crucial to scrutinize how business processes function and determine what can be automated and what needs to be preserved. After analyzing and modeling processes within the system's functionality, it may become apparent that certain business processes should be modified, and some might need to be entirely abandoned.

Combined Method

ERP system implementation occurs simultaneously across all areas but in a phased manner. This method allows for the expedited deployment of the system with minimal loss of work quality.

[Related Article: ERP vs CRM]

What components can an ERP system include?

Functional modules of an ERP system can be for internal or external use, incorporating tools for resource control (inventory, finances, human resources) and solutions for customers (personal accounts on the company's website, e-commerce solutions, etc.). Ideally, everyone formally interacting with the company, whether as a staff member, contractor, or customer, should have access to the system.

Traditionally, ERP systems consist of three groups of functional modules that cover financial, human resources, and operational accounting.

Financial Modules:

- Accounting software, financial control, and business strategy are integral parts of the program.

- All payment documents for fund allocation and payment pass through the ERP system.

- Production tracking, cost calculation of goods, assessment of investment attractiveness, and financial risks are managed through the system.

Human Resources Modules:

- Encompasses all aspects of personnel management, including payroll accounting, professional skills, time tracking, and employee efficiency.

- Career development, qualification enhancement, salary and pension accruals, and travel and bonus accounting are automated.

- Staff recruitment and training, as well as performance assessment, can be presented in numerical and graphical formats.

Operational Modules:

- Controls processes related to logistics, production, service, and sales.

- Issues related to supply, interactions with suppliers and customers, warehouse management, equipment maintenance, order processing, and distribution are handled automatically.

- Operational control extends beyond product interactions to possibilities such as changing the specifications or recipe of the production technology.

The implementation of an ERP system involves integrating several software components that can exist independently.

These include CRM systems (Customer Relationship Management) for managing customer relationships, PPM systems (Project Portfolio Management) for project portfolio management, PLM systems (Product Lifecycle Management) for product life cycle control, MES systems (Manufacturing Execution System) for production management, SCM systems (Supply Chain Management) for supply chain management, and many others.

Algorithm for Automation: Implementing an ERP System

First of all, you need to decide which processes will be automated and what is expected as a result. As a rule, companies that are thinking about ERP systems have some basic level of automation of individual processes. Consultants sometimes refer to this as "patchwork" automation.

Before implementing an ERP system, it is necessary to comprehensively analyze and describe the existing business processes to understand who and at what stages this or that information is needed and with what periodicity. The final cost of implementation depends on the definition of requirements for system functionality. Companies rarely use completely off-the-shelf products. As a rule, companies implementing technologies carry out refinements of systems according to the requests of a specific customer. However, it is necessary to understand that any refinement is an increase in the cost of implementing the system. Therefore, if, at the initial stage, it is not determined which functionality is really necessary, the company is at risk of an unjustified increase in the corresponding budget. And if the "bells and whistles" in the system are not used during daily operation, and vice versa - if the required functionality is not present in the system, the probability that the investment in automation will pay off for a very long time or will not pay off at all will increase.

In order to objectively choose the business processes that need to be automated, it is worth creating a working group in the company that will deal with implementation issues. It should consist of representatives of all services and divisions so that the needs of all departments are met as a result of implementation. Whether the process will be effective or whether it will drag on and only absorb financial, time, and human resources largely depends on the degree of involvement of the working group participants in the implementation process. The lion's share of unsuccessful implementations is explained by the reluctance of employees to delve deeply into this process. Successful implementation is always 50/50 (company effort -/+ implementing firm effort).

After determining the technical requirements for the system, it is worth thinking about the financial component of the issue. Initial license and implementation costs are only part of the cost. After the system is put into operation, costs for maintenance, refinement, basic maintenance, and version updates are added. All total costs must be estimated even before the purchase of an IT product in order to calculate the total cost of ownership of the selected system and, accordingly, predict the economic effect.

Before starting the tender, it is necessary to rank all the requirements for the system in order to correctly evaluate the proposals received from the implementing companies according to the agreed criteria.

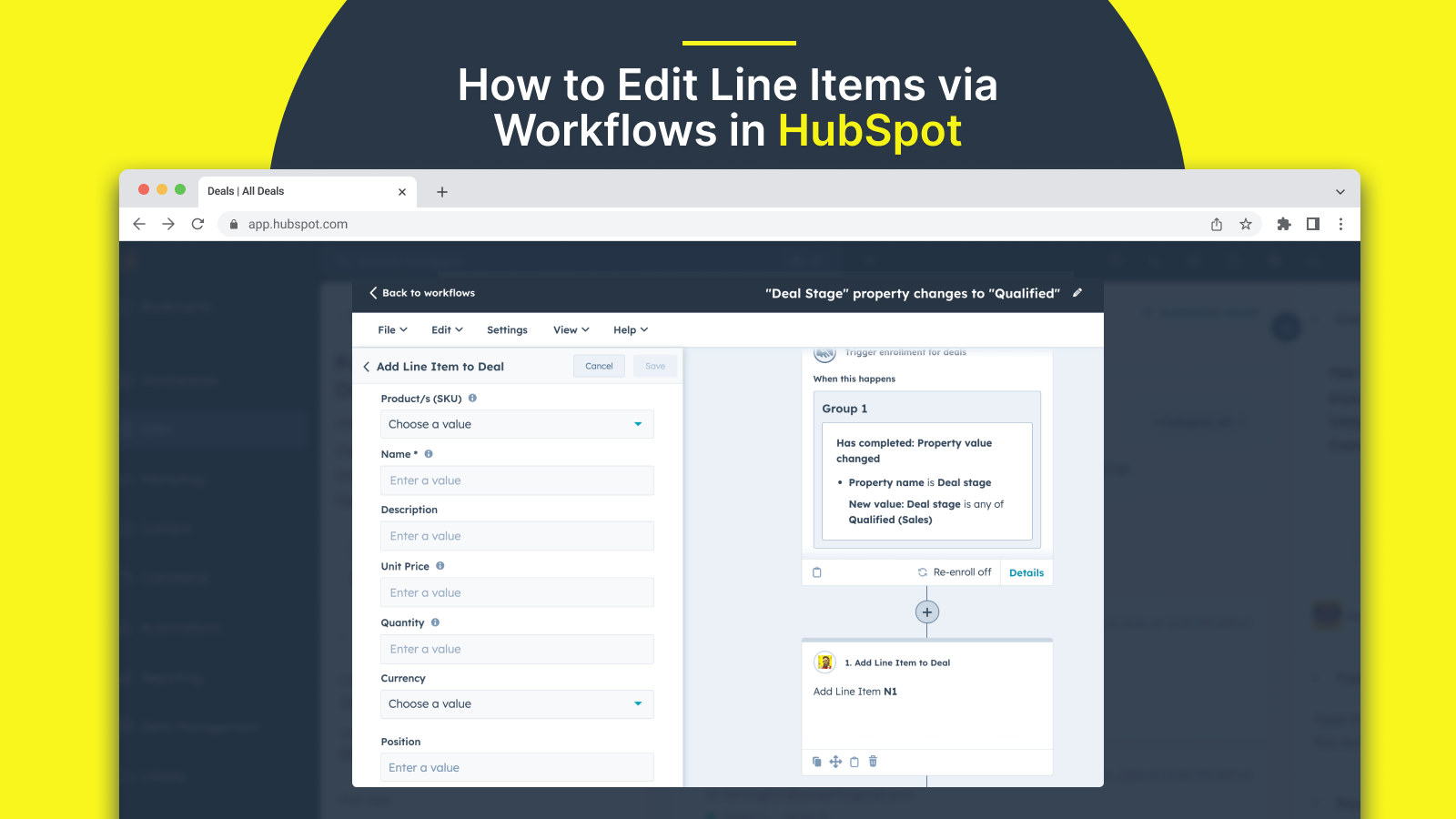

[Related Article: Top 10 Free HubSpot Apps]

Stages of ERP Implementation

The duration and complexity of ERP system implementation are determined by the necessity of comprehensive preliminary research into the company's operations. This may include:

- Company description: the number of employees, operational activities, production volume, etc. This is done for a better understanding, updating, or simply gaining a fresh perspective on routine tasks.

- Identification of processes already automated and those requiring automation.

- Identification of unique business processes that distinguish the company from competitors.

- Conducting interviews with owners of business processes, as in practice, employees often perform their functions differently than expected by managers (in theory).

- Modeling these business processes using selected options of software products or ERP systems.

- Compilation of a list of functional gaps—discrepancies between the typical functionality of the system and the described business processes of the company.

- Identification of possible constraints, risks, issues, and frameworks.

If the company's processes are streamlined and ready for implementation, you can proceed to project planning. At this stage, we recommend creating a detailed list of requirements for the ERP system, determining which areas of work to cover, outlining the project's scope, and deciding which departments to automate, among other considerations.

The implementation of an ERP system is an individual and responsible process. Therefore, the technology of implementation may include many stages, but the most common ones are:

Preparation for Implementation

Weighing the pros and cons, understanding whether ERP-based automation is genuinely needed for the organization. Defining goals and expectations, evaluating the desired budget, and project timelines.

Analysis and Planning

Conducting an analysis of the company, studying departmental work and business processes. This is a pre-project survey. Tasks are then defined, goals are set, and a technical project plan is formulated with subsequent modeling and optimization.

Design, Modeling, and Development

Experts prepare an adapted solution based on the requirements defined in the first stage. Key system modules, data loading needs, and integration settings with existing software are developed. The main business processes of the company are designed, and standard functionality is adapted to the specific activities of the enterprise.

Installation and Testing

Verification of data and system testing is conducted jointly with the customer's experts. In case of deficiencies, solutions are refined and prepared for industrial operation.

Initial Configuration of Reference Information (RI)

To efficiently manage the enterprise, a common information space must be created. This involves maintaining various directories that facilitate data entry.

Employee Training

This is a mandatory condition for the correct use of the ERP system in the enterprise. Typically, employees undergo an introductory course on using the product, and instructions may be created to prevent future user errors.

Deployment

Specialists configure accounting parameters and system configurations for the proper operation of the system. If necessary, adjustments are made in reports. At the final stage, problems arising from working with ERP can be identified and addressed.

Support

The company must decide in advance who and how will support the system in the future, whom to contact in case of issues. The choice can be between in-house specialists or an outsourcing company. An IT contractor can work hourly, on a task basis, or permanently on your premises.

What Businesses Gain from ERP Implementation: Advantages and Disadvantages

Primarily, an Enterprise Resource Planning (ERP) system is a way to consolidate all business processes, automate them, and make them simpler and more convenient. Therefore, it has numerous advantages. Here are just a few of them:

-

Versatility: Automation with ERP is possible in various types of production, and the system includes a wide range of tools for companies in different industries and scales. The program can be implemented not only in industry but also in banks, trade, services, etc.

-

Flexibility and Scalability: ERP is compatible with other configurations and applications. The system is easily customized for different business processes and scales to accommodate enterprises of various sizes, allowing for the management of corporations with a large number of divisions.

-

Unified Platform: Implementing an ERP system allows creating a unified information environment within the company, optimizing the work of departments, management, and employees.

-

Access Rights Distribution: ERP allows flexible distribution of access rights among employees of various departments, protecting valuable corporate data from unauthorized access.

-

Quality Planning and Accounting: ERP systems are designed to store and process a large volume of data. This information enables balanced resource allocation, accounting, and informed managerial decision-making.

The drawbacks of ERP systems arise from their advantages. Due to the numerous connections in the shared database, time is needed for configuring processes, transferring information, and adjusting operations (although, with advancements in recent years, this issue is less pronounced). It is necessary to ensure the uninterrupted operation of servers, implement software, purchase equipment to support processes, and organize staff training. Because of this, the initial cost of an ERP system may seem high, but one-time expenses are spread over the long term and pay off several times. Additionally, due to the scalability and power of the system, there is a limited number of specialists with experience and competence in ERP system implementation in the market.

Smart Business Management

In summary, ERP allows small companies to adopt the standards of the most rational business management. It enables the optimization of processes through automation and reduces costs through proper planning and resource utilization. Furthermore, the implementation of an ERP system is a smart investment for growing businesses, as it facilitates easy scalability and prepares them for dealing with Western markets.

If you want to learn more about how ERP solutions can assist in the development of your company, feel free to seek advice from experienced professionals.

.png)